What is the difference between wet and dry decapsulation?

The main difference between wet and dry decapsulation is the method used to remove the outer layers of the microelectronic device.

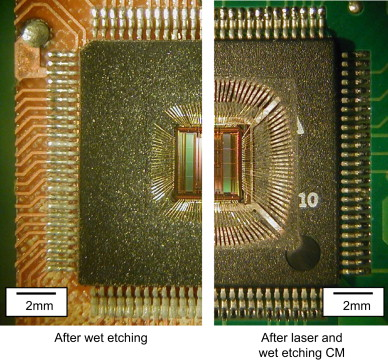

Wet decapsulation involves using a chemical solution or etchant to dissolve or remove the outer packaging material, such as a plastic or ceramic encapsulant, that covers the device. The device is submerged in the etchant, and the chemical reaction dissolves the encapsulant, exposing the underlying components. Wet decapsulation is often used when the encapsulant is soft or easily dissolved.

On the other hand, dry decapsulation involves using mechanical or laser techniques to remove the outer layers of the device. Mechanical decapsulation uses abrasive tools to mechanically grind or polish away the encapsulant layer, exposing the underlying components. Laser decapsulation, on the other hand, uses a laser beam to selectively remove the encapsulant layer, leaving the underlying components intact. Dry decapsulation is often used when the encapsulant is hard or difficult to dissolve using chemical etchants.

In both wet and dry decapsulation methods, the underlying components are exposed for further analysis to determine the root cause of any failure. Next, let’s take a look at the differences in processes between performing a wet vs dry decapsulation.

What is a step by step guide to chemically (wet) decapsulating a ceramic encapsulant?

Chemical decapsulation involves using chemical etchants to dissolve or remove the encapsulant layer. Here is a step-by-step guide to chemically decapsulating a ceramic encapsulant:

- Select the appropriate etchant based on the composition and thickness of the ceramic encapsulant. Common etchants for ceramic encapsulants include hydrofluoric acid (HF), phosphoric acid (H3PO4), or a mixture of sulfuric acid (H2SO4) and hydrogen peroxide (H2O2).

- Immerse the device in the etchant solution and agitate it gently to ensure that the etchant reaches all parts of the encapsulant layer.

- Monitor the progress of the etching process using microscopy or other imaging techniques. The etching time will depend on factors such as the composition and thickness of the encapsulant and the concentration and temperature of the etchant solution.

- Once the encapsulant layer has been removed, rinse the device thoroughly with deionized water to remove any residual etchant.

- Inspect the device using microscopy or other analytical techniques to ensure that the underlying components are intact and undamaged.

- If necessary, perform backside preparation to thin the device for further analysis.

It is important to note that chemical decapsulation can also be a hazardous process, and appropriate safety precautions must be taken to ensure that the etchant is handled and disposed of safely. Chemical decapsulation should only be performed by trained professionals with appropriate expertise and equipment.

What is a step by step guide to mechanically (dry)decapsulating a plastic encapsulant?

Mechanical decapsulation involves mechanically removing the encapsulant layer using abrasive tools. Here is a step-by-step guide to mechanically decapsulating a plastic encapsulant:

- Place the device on a mounting material, such as a vacuum chuck, to hold it securely during the decapsulation process.

- Use a diamond saw or blade to make a cut through the encapsulant layer, being careful not to cut through any of the underlying components.

- Use a series of abrasive tools, such as grinding wheels, polishing pads, or sandpaper, to remove the encapsulant layer gradually. Start with a coarse abrasive tool to remove the bulk of the encapsulant layer and then use progressively finer abrasives to achieve the desired level of decapsulation. The aim is to remove the encapsulant layer without damaging the underlying components.

- Inspect the device periodically during the decapsulation process using microscopy to ensure that the underlying components are not being damaged.

- Once the encapsulant layer has been removed, clean the surface of the device thoroughly to remove any residual debris or contaminants.

- If necessary, perform backside preparation to thin the device for further analysis.

It is important to note that mechanical decapsulation can be a time-consuming and delicate process, requiring careful control and monitoring of the decapsulation parameters. It is recommended that mechanical decapsulation be performed by trained professionals with appropriate expertise and equipment.