What’s the difference between plastic and ceramic chip packages?

Ceramic and plastic are two common materials used for chip packages in the electronics industry. Here are some of the main differences between them:

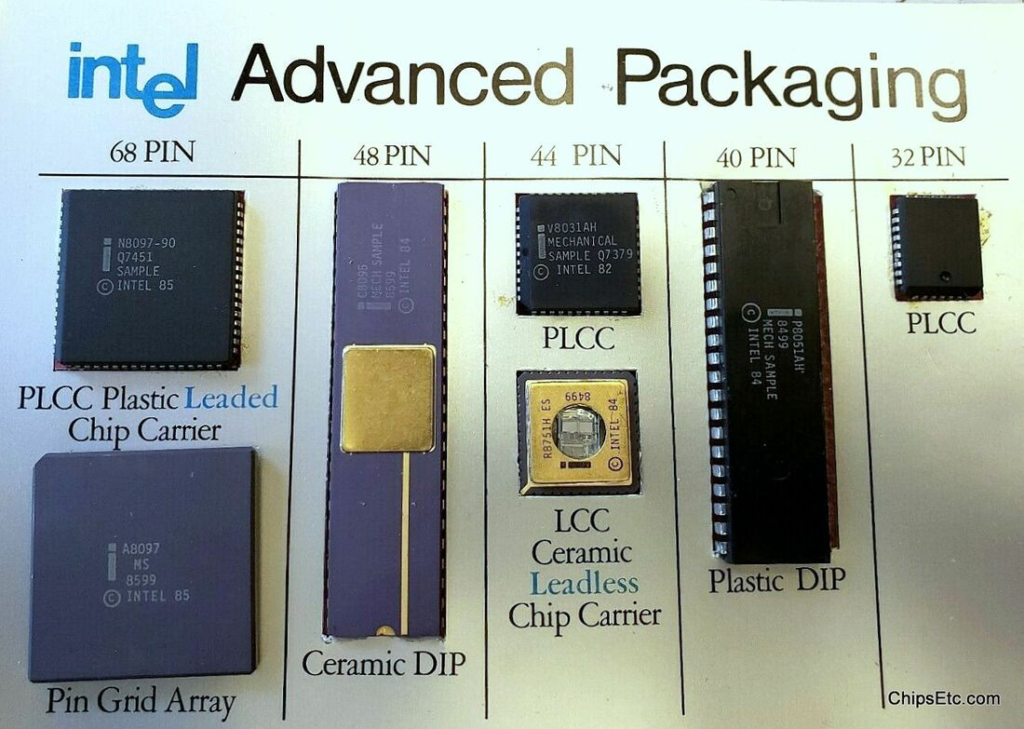

- Material: Ceramic packages are made of ceramic material, while plastic packages are made of plastic. Ceramic is more expensive than plastic, but it offers better thermal and electrical properties.

- Thermal properties: Ceramic has better thermal conductivity than plastic, which means it can dissipate heat more effectively. This makes ceramic packages more suitable for high-power applications where heat dissipation is critical.

- Electrical properties: Ceramic is also a better insulator than plastic, which makes it more suitable for high-frequency and high-voltage applications.

- Cost: Ceramic packages are more expensive than plastic packages due to the higher cost of the ceramic material and the manufacturing process.

- Size: Ceramic packages tend to be larger and heavier than plastic packages due to the need for a thicker material to provide adequate heat dissipation.

In summary, ceramic packages offer better thermal and electrical properties, but they are more expensive and larger than plastic packages. Plastic packages are less expensive and lighter, but they may not be suitable for high-power or high-frequency applications. Now that you know why your device may use different packaging materials, lets look at the implications for your decap process.

What’s the difference in decapping a ceramic vs plastic chip package?

Decapping is the process of removing the protective cover from a chip package to expose the integrated circuit inside. The decapping process can be different for ceramic and plastic chip packages due to the differences in their materials and construction.

Ceramic chip packages are typically decapped using a mixture of nitric and sulfuric acid, which dissolves the ceramic material and exposes the integrated circuit. This process is called acid decapsulation. However, this process is very harsh and requires specialized equipment and expertise to carry out safely. Ceramic packages are also more durable and resistant to environmental factors such as heat and moisture.

On the other hand, plastic chip packages are typically decapped using a hot sulfuric acid or organic solvent, which dissolves the plastic material and exposes the integrated circuit. This process is less harsh than acid decapsulation, but it can still be dangerous if not done properly. Plastic packages are less durable than ceramic packages and may be more susceptible to damage from environmental factors.

In summary, the decapping process can differ between ceramic and plastic chip packages due to their material properties and construction. Ceramic packages require a more aggressive acid decapsulation process, while plastic packages can be decapped with a less harsh solvent. Additionally, ceramic packages are typically more durable and resistant to environmental factors than plastic packages. Here at DecapLab, we routinely decap both package types.