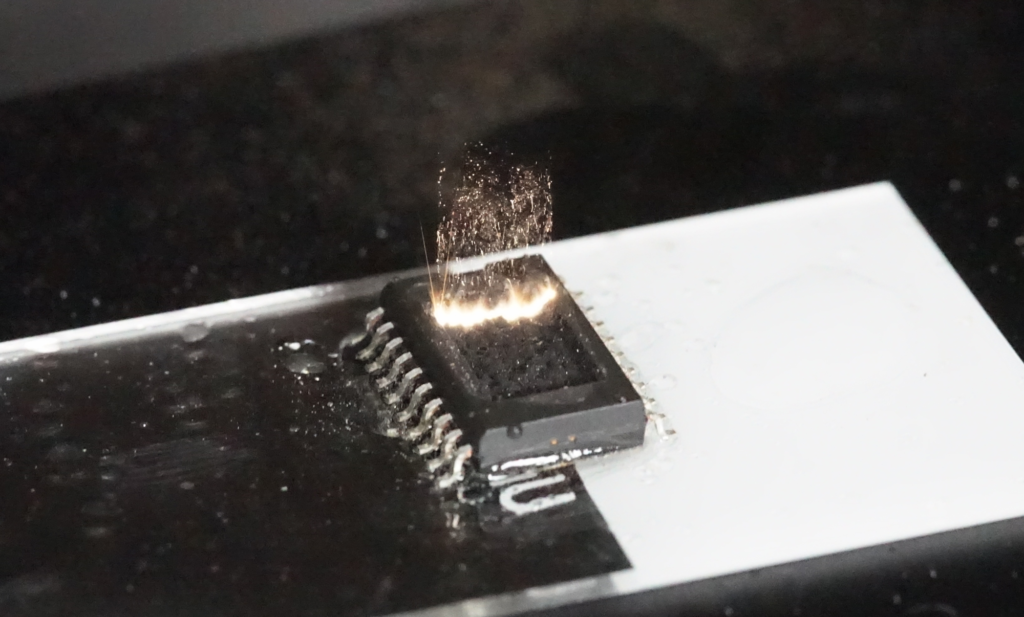

Laser-based decapsulation is an alternative method to traditional acid decapsulation for removing the protective cover from a chip package to expose the integrated circuit inside. This process uses a laser to ablate or vaporize the material covering the chip.

The laser used for decapsulation is typically a high-powered, pulsed laser, such as a Q-switched Nd:YAG or excimer laser. The laser energy is focused onto a small spot on the package surface, which causes localized heating and vaporization of the material. The laser beam is scanned over the surface of the package to remove the entire protective layer.

The advantage of laser-based decapsulation is that it is a non-contact and non-destructive method that can be used for a wide range of package materials, including ceramics and plastics. It also allows for precise control over the amount of material removed, which can be important for preserving the integrity of the integrated circuit inside.

However, laser-based decapsulation also has some limitations. It can be slower than acid or dry/mechanical decapsulation for very dense packages, and the equipment required for laser-based decapsulation can be expensive. Additionally, laser-based decapsulation may not be suitable for certain types of package materials or structures.

For example, in a study published in the Journal of Microelectronics and Electronic Packaging, laser-based decapsulation of a plastic package with a protective layer thickness of 100 micrometers was completed in about 30 seconds using a Q-switched Nd:YAG laser with a pulse duration of 10 nanoseconds. In another study published in the Journal of Electronic Packaging, laser decapsulation of a ceramic package with a protective layer thickness of 180 micrometers was completed in about 2 minutes using an excimer laser.

However, the actual time required for laser decapsulation can vary depending on the specific laser used, the material of the package, and other factors. Additionally, the time required for laser decapsulation can be affected by the need to adjust laser parameters or the need to perform multiple passes over the same area to fully remove the protective layer.

In summary, laser-based decapsulation is a non-contact and non-destructive method for removing the protective cover from a chip package using a high-powered pulsed laser. While it has some advantages over traditional acid decapsulation, it also has some limitations and may not be suitable for all types of package materials or structures. As your decap partner and advisor, we will recommend the best decap type for your packages, cost, and size requirements.